How does FDM 3D printer work?

Introduction

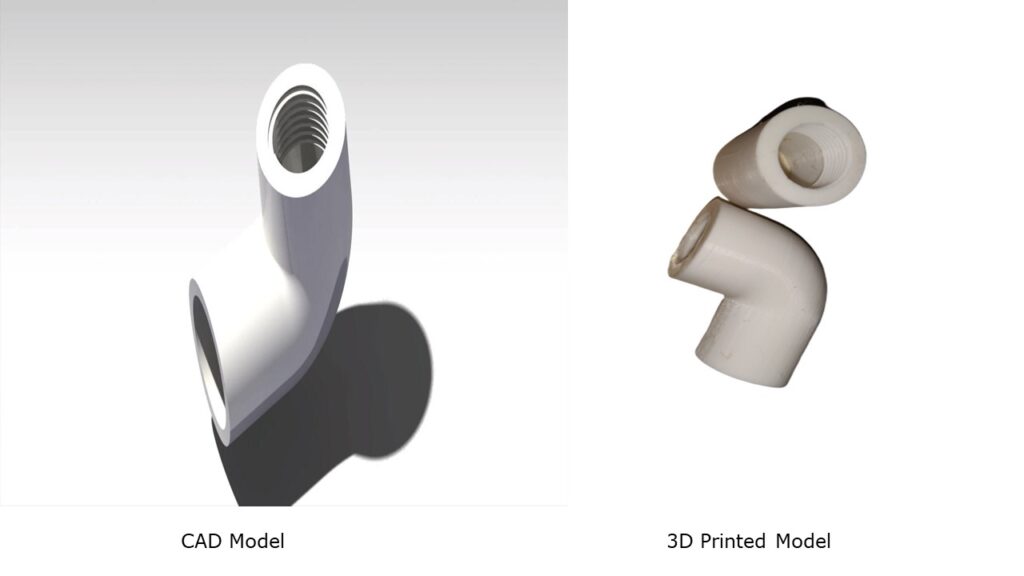

FDM (Fused Deposition Modelling) or FFF (Fused Filament Fabrication), is an additive manufacturing process by depositing material layer by layer. FDM is the most commonly used 3D printing technology in the world. It is cost-effective compared to other 3D printing technologies.

Thermoplastic materials like PLA, ABS, PETG, TPU, and exotic materials like metal or wood infused thermoplastics are used in FDM 3D printers. the FDM 3D printer consists of a printing platform, nozzle, and printing material in a form of filament.

FDM working principle

The thermoplastic material is loaded into the printer. Once the nozzle attains the desired temperature extruder fed the material to the nozzle where it melts. The extrusion head moves in X, Y, and Z directions. the melted material gets deposited layer by layer in a predetermined location where it gets cool and solidify. The cooling fans are additionally used for cooling the material.

When the layer is finished either the build platform moves down or extruder head moves up to form a new layer. Most FDM printer first prints the outer edges, interior edges next, and lastly the interior of the layer as either a solid layer or as a fill-in matrix.

In some models, some overhangs will droop unless they are given some support. These support structures are printed along with the object. Later, it can be removed.

More to know

In June 2017 NASA launches 3D printed satellite called KALAMSAT which is the world’s smallest and lightest satellite designed by 18-year-old Rifath sharook from India.

Advantages

The thermoplastic material is inexpensive, durable, and maintains dimensions of integrity.

Material flexibility it has a wide choice of raw material.

The lead time is short compared to other 3D printing technology.

Disadvantages

The layer lines are visible. So post-processing is required for a smooth finish.

Intricate prints are hard to achieve.

It leads to warping and minor shrinking.

The layer lines are visible

FDM 3D printer types

There are 4 major FDM 3D printers in the market.

Cartesian FDM printer.

Delta FDM printer.

Polar FDM printer.

Robotic Arm FDM printer.

Among these Cartesian and Delta printers are widely available in the market.